Cosworth Engines

[ Vol.1 | Vol.2 | Vol.3 | Vol.4 | Vol.5 ]

[ Vol.1 - Modified OHV | SCA | FVA | BDA ]

[ Vol.2 - DFV | DFV in Japan ]

[ Vol.3 - Fomula 1 | Indy/Champ car ]

[ Vol.4 - inline 4 ]

[ Vol.5 - Others ]

| DFV Variant |

| Type | Year | Config. | B x S | Disp. | Output | Weight | Description | ||

|---|---|---|---|---|---|---|---|---|---|

| DFV | 1967-82 | V8 | 90 | 85.7 x 64.8 | 2993cc | 405Bhp. | 9,000rpm | 168 kg | The most successful GP engine of all time, 155 victories 1967-83, the first engine completely designed by Cosworth |

| DFW | 1968 | V8 | 90 | - | 2491cc | 358 Bhp. | - | - | Short stroke DFV for Lotus in the Tasman, engines converted back to DFVs |

| DFX | 1975 | V8 | 90 | - | 2645cc | 840 Bhp. | - | - | Short stroke Indy turbo engine, boost limited to 80 in. | 1986 | V8 | 90 | - | 700 Bhp. | - | - | Rules reduced boost to 48 in., the most successful Indy engine of the 80s |

| DFL | 1981 | V8 | 90 | - | 3955cc | 540Bhp. | - | - | Group C endurance version, larger bore and stroke | 1981 | V8 | 90 | - | 3298cc | 490 Bhp. | - | - | short stroke DFL for C2 cars |

| DFV | 1982-84 | V8 | 90 | - | 2993cc | 500 Bhp. | 11,100rpm | 168 kg | Short Stroke DFV, DFL bore, better power for F1 |

| DFY | 1983 | V8 | 90 | 90 x 58.8 | 2993cc | 500-520 Bhp. | 11,000rpm | 150 kg | Further development of short stroke DFV with narrower valve angle heads, F1 only |

| DFV (F3000) |

1986 | V8 | 90 | - | 2993cc | 420 Bhp. | - | - | Special for Formula 3000, rev limited to 9000 |

| DFZ | 1987-88 | V8 | 90 | 90 x 68.7 | 3494cc | 560 Bhp. | 10,500rpm | - | Post turbo-era F1 3.5 aspro |

| DFR | 1988-91 | V8 | 90 | 90 x 68.7 | 3494cc | 595+ Bhp. | 11,000 -12,000rpm |

155 kg | Fully updated F1 DFZ, new heads, Benneton for '88, widely used '89 |

| DFS | 1988-89 | V8 | 90 | - | 2645cc | - | - | - | Modernized DFX for CART/Indy using DFR experience |

|  |

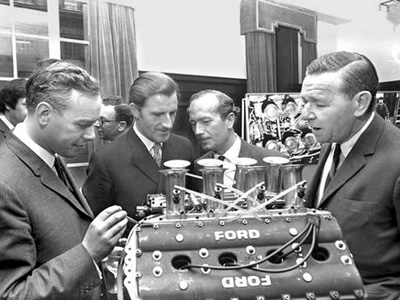

| 1967 Bill Brown, Keith Duckworth, Mike Costin and Ben Rood | 1967 Keith Duckworth, Colin Chapman, Jim Clark and Graham Hill |

|  |

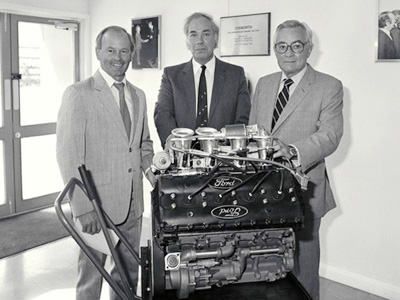

| 1986 Costin, Duckworth and Walter Hayes(Ford UK) | 1967 Keith Duckworth, Graham Hill, Colin Chapman and Haley Copp(Ford UK) |

1966: The DFV (Double Four Valve)

In late 1964, the FIA issued the regulations that would govern Formula 1 starting in 1966. The new rules allowed a maximum engine capacity of 3.0 liters or 1.5 liters supercharged. Also in 1964 Leonard Lee announced that Coventry Climax would not continue as an engine provider after 1965. With Coventry Climax’s withdrawal from the sport the British teams, excluding BRM, would require a new engine supplier. Cooper entered an alliance with Maserati for use of its V12 engine. Brabham went for simplicity with Repco of Australia developing SOHC cylinder heads for the aluminum Oldsmobile F85 V8 cylinder block. Lotus signed a short-term deal with BRM to use its new H16 engine. The BRM engine would not be ready until late in the season so Lotus owner Colin Chapman convinced Leonard Lee to provide a 2.0 liter upgrade to the Coventry Climax engine for Lotus to use in 1966.Chapman approached the Motor Manufactures and Traders for backing of a new Formula 1 engine with no success. He also made an early approach to Ford and was rebuffed. David Brown was interested but wanted more control than Chapman was willing to concede. There were changes at Ford that would soon work in Chapman’s favor. Journalist Walter Hayes joined the company as Director of Public Relations and shortly after joining he decided that Ford would support motorsports for promotional purposes. Hayes was meeting Chapman socially and eventually Chapman shared that he was not having success finding an engine for his Lotus team. He casually asked Hayes if Ford would be interested in funding a Formula 1 engine. Hayes was interested and discussed the idea of Ford funding a F1 engine to Harley Copp, Ford’s Vice President of Engineering. Copp, a racing enthusiast, was introduced to Chapman by Hayes. Chapman suggested that Keith Duckworth could design the engine. After reviewing the plans for the Cosworth’s FVA Formula 2 engine Copp became an enthusiast supporter of the project.

Keith Duckworth had worked for Lotus after graduating from university. While there he developed a friendship with Mike Costin. Duckworth became disillusioned at Lotus and suggest that he and Costin form a company to build racing engines. Costin was interested but with family responsibilities elected to stay at Lotus, although temporally, as Technical Director. In 1958 Duckworth and Costin formed Cosworth engineering with Duckworth as the primary shareholder and first employee. Mike Costin joined full time when his Lotus contract expired.

Duckworth was approached and a contract with Ford was completed. Ford would fund the development of a 1.6-liter Formula 2 engine and, if successful the second half of the contract would be for the design and manufacture of a 3.0 liter Formula 1 engine. The terms of the contract provided Lotus with exclusive use of the first five engines for 1967. The contract, valued at GBP100,000 ($323,000 in US dollars), would use the first GBP25,000 for the design and production of a Formula 2 engine. The engine was designated FVA for Four-Valve A series. Duckworth designed a twin overhead camshaft aluminum alloy cylinder head for the Ford Cortina 5-bearing 120E cylinder block. The two camshafts were driven by a chain of eight gears from the crankshaft. The engine introduced the narrow-angle cylinder head and would generate over 220 bhp at 9,000 rpm. The engine was running on the test bed in February of 1966 and Mike Costin was testing the engine in a Brabham chassis in the summer of 1966. The engine met all of the goals that were set and based on it success approval was given for the design of the 3.0 liter Formula 1 engine. The FVA would dominate Formula 2 racing from 1967 to 1971.

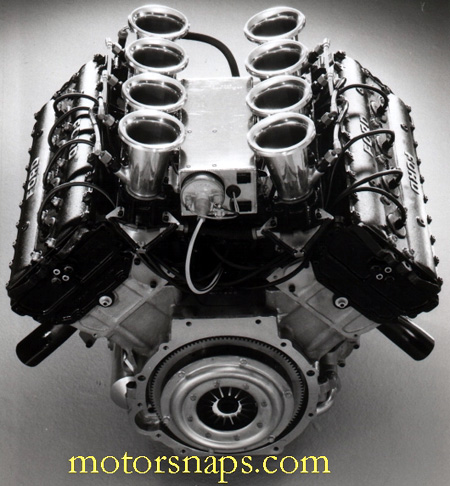

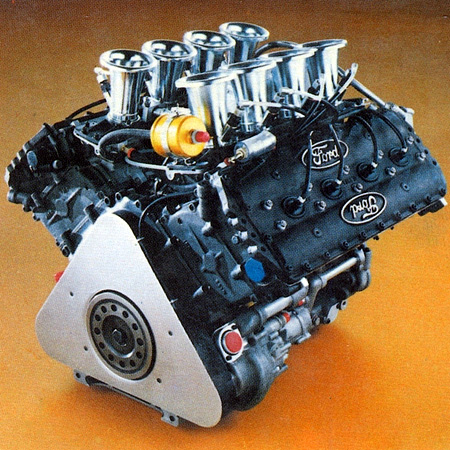

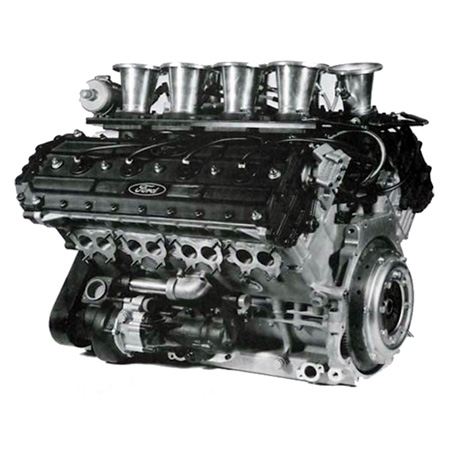

The Formula 1 engine would use the concepts developed and proven with the Formula 2 engine. Duckworth decided on a compact V8 instead of a large, complex engine like the BRM H16. For the GBP75,000 that Ford would spend, the company’s name would be placed on the camshaft covers. The engine was given project code DFV for Double Four-Valve. Mike Hall assisted Duckworth with the design. Hall did the detail design work on the oil and water pumps, fuel metering unit and the alternator. Duckworth was responsible for the rest of the engine. As Cosworth was working on the engine, Lotus was designing the Type 49 to carry it. The two companies worked closely to integrated the engine and chassis. Lotus designed the 49 with the DFV as an integral part of the concept. The DFV would be mounted with four bolts to the chassis. Two passing through an aluminum bracket at the bottom of the engine and two on straps from the camshaft covers to the monocoque. The engine would be used as a load-bearing chassis member allowing it to be directly mounted to the rear of the monocoque chassis.

When Cosworth first ran the DFV it was discovered that the oil was not draining down from the cylinder heads. After trying various fixes, Cosworth cut holes in the cam-covers and added aluminum collector boxes with drain pipes to return oil to the sump. The first DFV was handed over to Lotus on 25 April 1967 and the car and engine debuted at the Dutch Grand Prix. The race has become part of Formula 1 folklore with Jim Clark winning on the car and engine’s debut. Clark would go on to win three more races in 1967. The Lotus and Cosworth combination was fast and would be the dominate car of the year. If Clark finished he normally would win. Lotus worked to improve the reliability of the 49 and Cosworth had to overcome problems with oil drainage and torsional vibrations in the valve train.

Hayes recognized that the engine would dominate Formula 1 and if not provided to other teams had the potential to ruin Formula 1. He suggested to Chapman that the engine would need to be made available to other teams and reluctantly Chapman agreed. McLaren and Matra would use the engine in 1968 and in 1969 every championship event was won by DFV powered cars. As Cosworth production and rebuilding capabilities expanded Formula 1 was set for significant growth setting the stage for the modern Formula 1 era. Soon any team could purchase an engine from Cosworth a gearbox from Hewland, design and build a chassis and they were ready to go Formula 1 racing.

When Ferrari would experience one of its periodic renaissances, Cosworth would develop the engine to improve its power and reliability. As underbody aerodynamics were exploited the ancillary components would be modified, but the basic engine would win Formula 1 races over the next twelve seasons. In the late 1970s Ford was black listed by a number of mid-east countries. Formula 1 teams were looking at the oil rich kingdoms for sponsorship and to overcome the objection to Ford, new cam covers were created using Cosworth instead of Ford.

Although Duckworth was adamant that the DFV was a Formula 1 engine, it would also power endurance cars, winning the 24 hours of Le Mans twice. A de-stroked 2.65-liter turbo-charged version would dominate CART racing into the 1980s. When Formula 2 was replaced by Formula F3000 in the mid 80s a new market was opened for the DFV.

A Ford-Cosworth DFV installed in the back of a Lotus 49 in 1966, Colin Chapman (Lotus Cars founder and principal of Team Lotus) persuaded Ford to bankroll Keith Duckworth's design for a new lightweight 3,000 cc Formula One engine.

Cosworth received the order along with the £100,000 that Ford felt it adequate to spend on such an objective. The contract stipulated that a four-cylinder Ford-based F2 engine would be developed as proof of concept (see the FVA above) and that a pure Cosworth V8 would be built based on this.

The DFV design used a similar cylinder head to the one Duckworth had prototyped on the four-cylinder FVA units on a custom Cosworth cylinder block and crankcase, forming a single 90° V8 engine, thus creating a legend in its own right, the DFV - literally meaning "Double Four Valve". This engine, and its derivatives were used for a quarter of a century, and it was the most successful in the history of Formula One / Grand Prix motor racing. Winning 167 races in a career lasting over 20 years, it was the product that put Cosworth Engineering on the map. Although originally designed for Formula One, the engine has been modified to be used in a range of categories.

The DFV won on its first outing, at the 1967 Dutch Grand Prix in the hands of Jim Clark, fitted to a Lotus 49, and from 1968 was available for purchase to any F1 team that wished it.

During the 1970s, it was common for almost the entire field (with the notable exception of Ferrari) to use one of these engines - this at a time when independent wealthy individuals could buy exactly the same engine off the shelf that was also being used by McLaren et al.

Most teams just built a tub around a Cosworth DFV and a Hewland gearbox. It won a record 155 World Championship races, the last being Detroit in 1983, powering a Tyrrell driven by Michele Alboreto.

Although the DFV (bore: 85.67 mm, stroke: 64.90 mm, displacement: 2,992.98 cc) with 410 bhp (306 kW; 416 PS) at 9,000 rpm did not produce as much power as some of its rival 12-cylinder engines, it was lighter, resulting in a better power to weight ratio.

In addition to being lighter, it was also made a structural part of the car itself, by placing load bearing arms to stress the block. These design aspects appealed tremendously to the genius of Colin Chapman who used them to the fullest extent.

DFV on sports car

The first sports car to use a DFV, the Ford P68, failed to finish a single race because of repeated mechanical and electrical failures. Despite this handicap the DFV won the 24 hours of Le Mans twice in its original 3.0-litre form for Mirage and Rondeau (although the Mirage win in 1975 was with a significantly de-tuned unit).1968: Ford P68

1968 FORD P68

1975 LeMans Winner

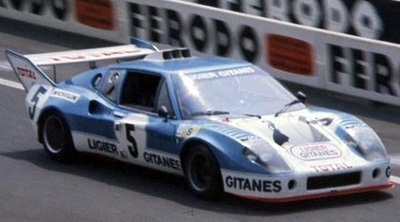

2nd: 5 Jean-Louis Lafosse/Guy Chasseuil - Ligier JS2 - Ford Cosworth DFV 3.0L

3rd: 10 Vern Schuppan/Jean-Pierre Jaussaud - Mirage GR8 - Ford Cosworth DFV 3.0L

1980 LeMans Winner

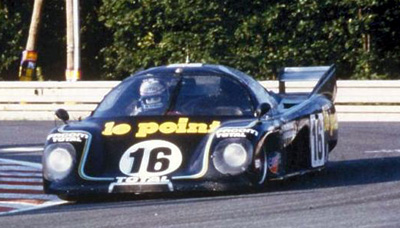

3rd: 17 Gordon Spice/Philippe Martin/Jean-Michel Martin - Rondeau M379 - Ford Cosworth DFV 3.0L

1968: DFW for Tasman Series

The DFV spawned a number of derivations. In 1968; Cosworth created the DFV's first derivation, a 2,500 cc version for the Tasman Series, the DFW. DFV to DFW conversion simply involved substitution of a short-stroke crank and longer connecting rods aka conrods.

Lotus 49T ('T' means 'Tasman')

1975: DFX for IndyCar

One of the most successful and longest-lived projects of Cosworth has been its CART / Champ Car engine program.

In 1975; Cosworth developed the DFX, by destroking the engine to 2,650 cc and adding a turbocharger, the DFX became the standard engine to run in IndyCar racing, ending the reign of the Offenhauser, and maintaining that position until the late 1980s.

DFL for Endurance race

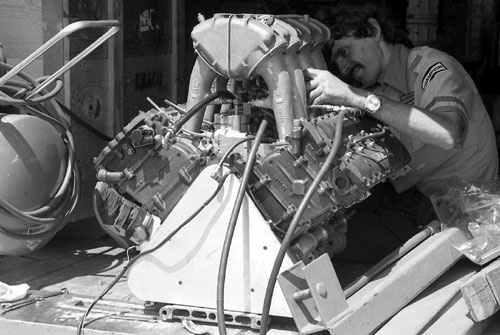

1981 DFL

While designed as an F1 engine, the DFV was also used as in endurance racing, although its flat-plane design led to destructive vibrations putting stress on devices surrounding the engine, especially the exhaust system.

1987 DFL

A special endurance version, the DFL, was then developed in two versions: one with 3,298 cc and the other with 3,955 cc. Whilst the former version soon became known for its reliability, the latter version was a step too far and is largely remembered as a failure.

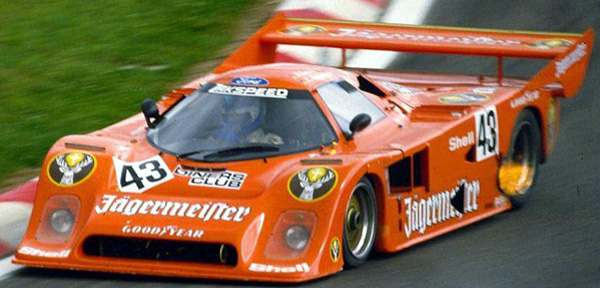

DFL on FORD C100

The car that appeared in the group 6 race in 1981 was the first version of the C100 designed by Len Bailey at a time where the group c regulations were very vague and not detailed initialized by Karl Ludvigsen.

The car featured a sheet aluminium monocoque on a base of a Tyrell F1 monocoque and was powered by 3,3 l Ford Cosworth engine.

After some political problems Len Bailey left the project and the whole development was transferred to Ford Cologne where the former Porsche employee Eberhard Braun together with six guys analized the car.

The car didn't fulfil the new group c regulations in the main dimensions and had weak points almost everywhere. The chassis was too weak, the rear and front subframes too, the suspension didn't work cause the geometry of the rocker arms where wrong and so on. The car was desribed as undriveable.

The problem was a lack of time and Mr. Braun was a specialist in tubular frames but not in monocoques. He and his team did some stress analysis stiffed the monocoque and the subframe, reworked the suspension and created a totally new aerodynamics with some advanced features in the underbody design.

After the things they had heard on the new 3,9 DFL Cosworth engine it should be better in terms of fuel consumption as the Porsche. The reality was the engine was down on power ( not reaching the official 540 bhp), need more fuel and showed terrible vibrations caused by the flat plane crankshaft. Nobody of the Ford officials tried something against Cosworth.

After a few test miles the car started at a test race in the DRM and then in Monza not really showing a great performance. After the Monza race K. Ludvigsen moved the whole further development from Cologne to the Zakspeed Racing at Niederzissen. Peter Ashmore asked Tony Southgate to have a look at the car. He realized still weak areas in the chassis and subframe stiffness and the suspension. He did a new alu honeycomb monocoque ( built by T.C. Prototypes), designed new subframes and a revised suspension. This car was about 2,5 seconds faster occuring the pole position at the Nurburgring.

Ludvigsen wanted a totally new car for 1983 powered by a turbo version of the DFL engine. As a race team Gordon Spice was engaged and Tony Southgate did the new design with an intensive wind tunnel work at Imperial College. The car showed some features of the later Jaguars like horizontal skirts at the lower edge of the sidepods. A totally new underbody with short tail and a twin element rear wing working in interaction with the venturi tunnels were the main features.

The chassis was a honeycomb aluminium monocoque built by T.C Prototypes. The car did some tests at Paul Ricard with the old 3,9 DFl engine and showed impressive speed. After Ludvigsen left Ford and Stuart Turner did his job he immidiately cancelled the whole project.

Zakspeed's Helmut Barth revised the MK-II cars by moving the water radiator from the sidepods to the front, developing a new rear aero and fitted it with inline 4 cylinder Zakspeed engine called C1/4. A version with a V8 Cosworth engine was also run ( C1/8) mainly in the DRM. Success was lot really impressive.

At the whole Ford project there was too much politics and rivalry between Ford England and Ford germany. A work of a whole sports department with the will to succeed never existed.

1982: DFY

The DFY, introduced in 1982 was a further evolution of the DFV for Formula One, with a shorter stroke and a DFL bore (bore: 89.99 mm, stroke: 58.83 mm, displacement 2,993.38 cc) with 520 bhp (388 kW; 527 PS) at 11,000 rpm, thereby producing more power, but still unable to fight against the turbocharged cars of the day.

1986: DFV for Formula 3000

It was the advent of turbocharged engines in Formula One which sounded the death knell for the venerable DFV, and in 1986 Cosworth returned to the lower formulae preparing the DFV for the newly created Formula 3000, with the installation of a compulsory 9,000 rpm rev limiter, which scaled power back from 500 to 420 bhp (313 kW; 426 PS); the DFV remained in this class until 1992. The final F3000 engines gave 500 bhp (373 kW; 507 PS), almost equalling the 1983 DFV which gave 510 bhp (380 kW; 517 PS) at 11,200 rpm.

1987: DFZ

In Formula One, a new DFV-based design was introduced for the new 3,500 cc normally aspirated rules in 1987.

1988: DFR

The DFZ was produced as an interim model, but in 1988 Cosworth created the DFV's final evolution, the DFR, which soldiered on in F1 with smaller teams until 1991, scoring its last points - including a pair of second places by Jean Alesi - with Tyrrell in 1990.

The DFV has recently been given a new lease of life thanks to the interest in Classic F1 racing, which was given a World Championship status by the FIA in 2004.

1988-89: DFS for IndyCar

Ford backed Cosworth with creating a new interim design for IndyCar racing in the late 1980s, the DFS, which merged DFR technology into the ageing DFX design, but it was eventually rendered obsolete by advancing technology.

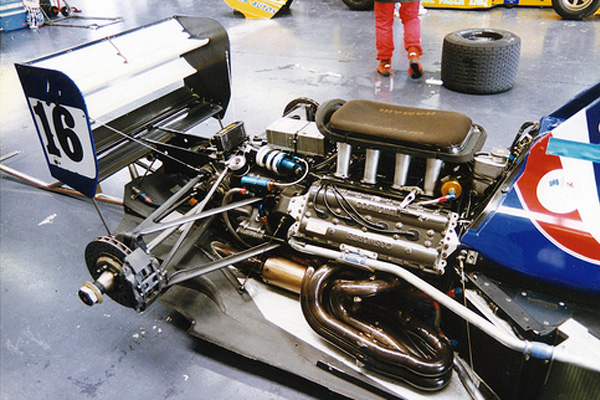

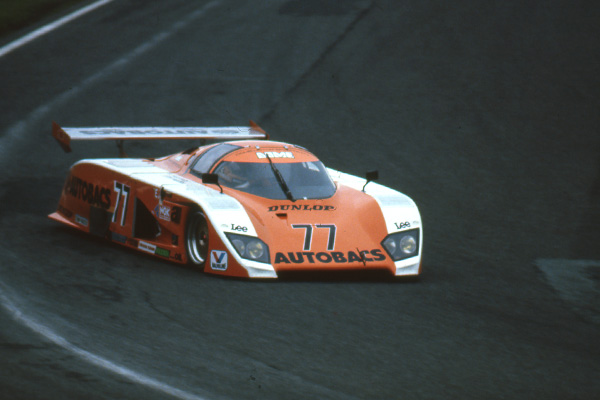

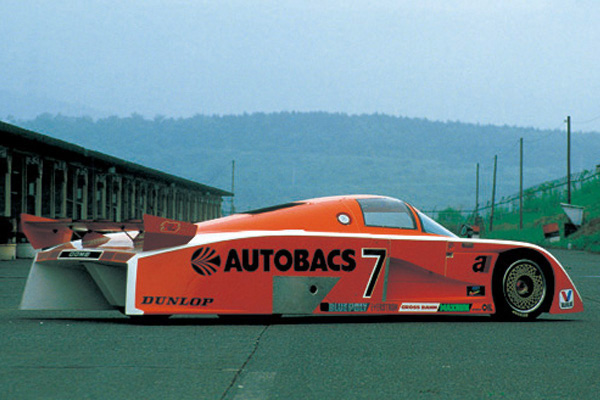

Japanese obscure newcomers with the DFV

MAKI

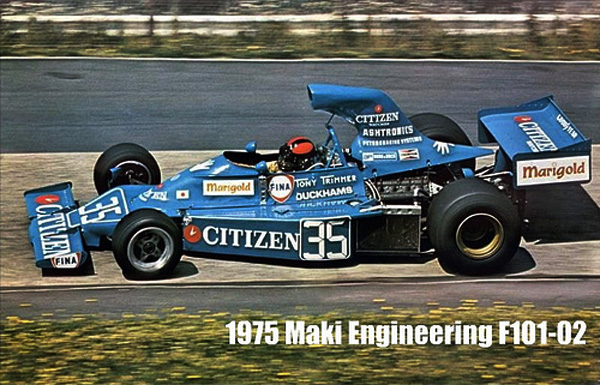

「マナ」や「エバカーズ」といったコンストラクターでF2やGCなどのレーシングマシンを設計製作していた三村建治を中心として、1973年、「マキエンジニアリング」が発足した。メインスポンサーは「エムズブレイン」というネズミ講の会社で、「マキ」はエムズブレイン社長、牧に由来する。マキは、1974年、突如、F101を登場させた。三村がボディデザイン、小野昌朗がシャシーを担当した。エンジンはフォード・コスワース・DFV。

74年から76年にかけ、F1世界選手権に計7戦エントリーしたが、75年のノンタイトル戦スイスGPの決勝13位以外には1度も決勝進出を果たせなかった。

1974: MAKI F101

Howden Ganley a Brands Hatch, durante le prove del Gran Premio di Gran Bretagna del 1974

長野県上田市のドライブインに長年展示されていたF101は、1974年に製作された4台のうち、スペアとして日本に残されていて、F1の実戦は走っていないものだったが、2009年、市立広島工業高等学校の自動車部らがレストアを行った。(実戦を走った車台は海外のコレクターが所有している) カウルデザインはイギリスで大幅に変更された経緯があり、このレストアされたカウルがオリジナルデザインである。(展示車はエンジンレスのため、リアウイングが固定されていない)

1975: MAKI F101-02

Hiroshi Fushida impegnato a Silverstone in 1975

1976: MAKI F102

Tony Trimmer at Fuji in 1976

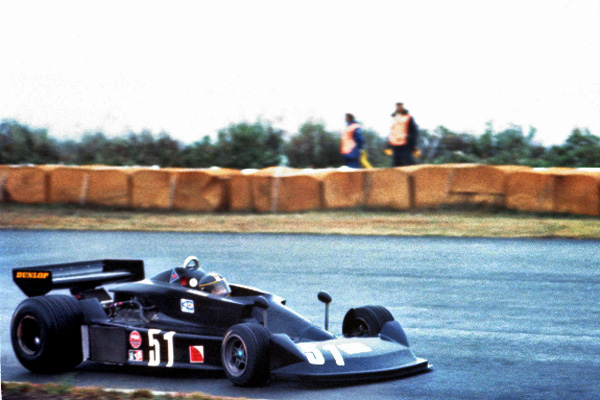

1976: KOJIMA KE007

1976年のF1選手権イン・ジャパンに参戦するためだけに開発された。シャーシ設計は、マキF101の車体設計を担当した小野昌朗、カウルデザインは由良拓也。ドライバーは長谷見昌弘。純国産にこだわり、日本ダンロップのタイヤ、カヤバ工業のショックアブソーバー等を採用したが、エンジンはコスワースDFV、ギアボックスはヒューランド、ブレーキはロッキードであった。

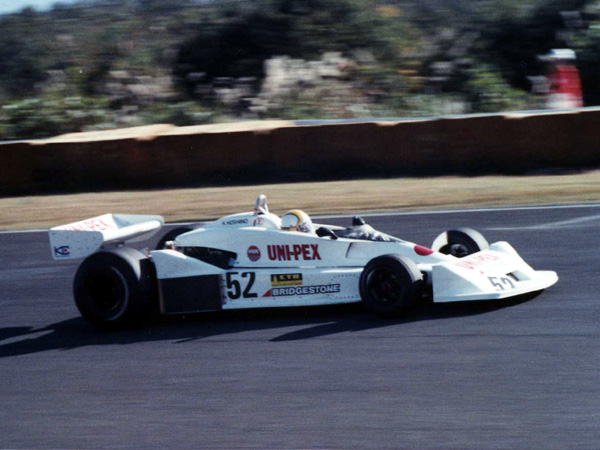

1977: KOJIMA KE009

KE008のコードは、同じモノコックシャーシを持つF2マシンに与えられた。KE008は高橋国光、長谷見昌弘らのドライブにより1977年、78年の全日本F2選手権で活躍する。KE009は前作KE007の改良版。星野一義車がUNI-PEX、高原敬武車が伊太利屋のスポンサーを得た。タイヤはF1未経験のブリヂストン。

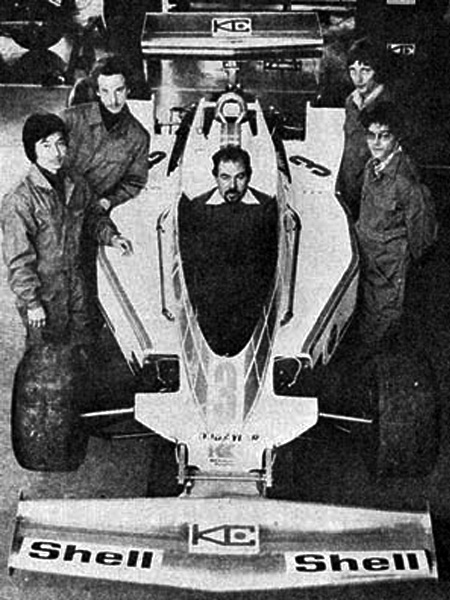

1977: KOJIMA KE009B

1977年シーズン終了後、ドイツのWKRT(ウイリー・カウンゼンレーシングチーム)からジョイントで1978年のF1フル参戦を持ち掛けられたが、資金の問題で計画は消滅した。(カウンゼン側には、日本から車両を持ち出す資金もなかったとか、あるいは日本から2台送ったものの、そのまま戻ってこなかった、とか諸説ある)

シートに収まるのは、チームオーナー兼ドライバーであるウイリー・カウンゼン

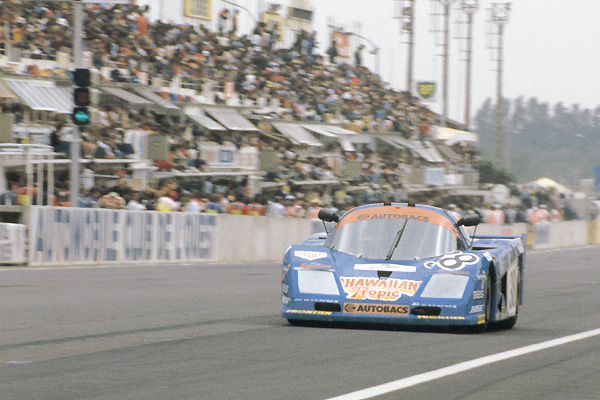

1979: DOME RL

林ミノル率いる童夢がル・マン24時間レースに送り込んだGr.6マシン。エンジンはコスワースDFV。総合優勝を狙うクラスに初めてエントリーした日本製マシン。参戦した2台は、予選15、18番手につけ、決勝では当初トップ・グループを快走したが、レースはわずか1時間半で終わってしまう。

1980: DOME ZERO RL80

前年のRLを改良し。ル・マン24時間レースに再挑戦。予選7位を得るが、決勝では早々とミッション・トラブルが発生し、3時間近い修復作業を余儀なくされるも完走、25位というリザルトを得た。

1981: DOME RL-81

ル・マン24時間レース、予選20位。決勝リタイア。

1982: DOME RC-82

童夢が設計、英国のマーチグランプリ社が製作。ル・マン24時間耐久レースに出場。予選20位、決勝リタイア。エンジンは3.9LのコスワースDFL。

1983: DOME RC-82i

前年のRC82を英国で改良。ル・マン24時間レースに出場。エンジンはコスワースDFL。

1983: DOME RC-83

童夢最初の国内耐久レースカー。1984年のル・マン24時間レースに出場。予選21位、決勝出走せず。エンジンはコスワースDFL。

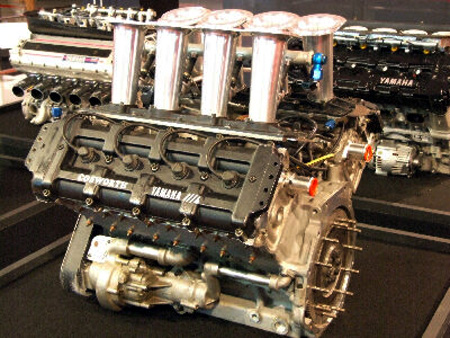

1987-88: YAMAHA OX77 - DFV with YAMAHA 5valve head

F3000用コスワースDFVのヘッドをヤマハが5バルブ化したOX77は、1987年と88年の2年間、全日本F3000選手権で使用された。鈴木亜久里により88年のチャンピオンエンジンとなっている。

1985年、ヤマハは、全日本F2選手権および富士グランドチャンピオンシリーズに初の4輪レーシング・エンジン、OX66で参戦を開始する。OX66は、1995cc・75度V6DOHC5バルブで330馬力以上を叩き出した。

1987年、F-2規定がF-3000となり、全日本F3000にOX77を投入。

F1が全車NAエンジンとなる1989年より、ザクスピードにエンジンを供給する形でF1に参戦を開始した。当初、コスワースDFRを5バルブ化したものを使用する予定であったが、結局、75度DOHC-V8・5バルブエンジンのOX88は完全にヤマハオリジナルとなった。

ドライバーはドイツ人のベルント・シュナイダーと鈴木亜久里であったが、シーズンを通してシュナイダーは予選通過に2回のみ、鈴木亜久里は16戦全戦予備予選不通加という惨憺たる結果に終わった。

1990年はザクスピードの撤退でエンジン供給先がなくなり、翌1991年にブラバムへ5バルブV12エンジンのOX99を供給し復活を果たす。